History of Himi-Bari(Himi-Needle)

(1) Beginning

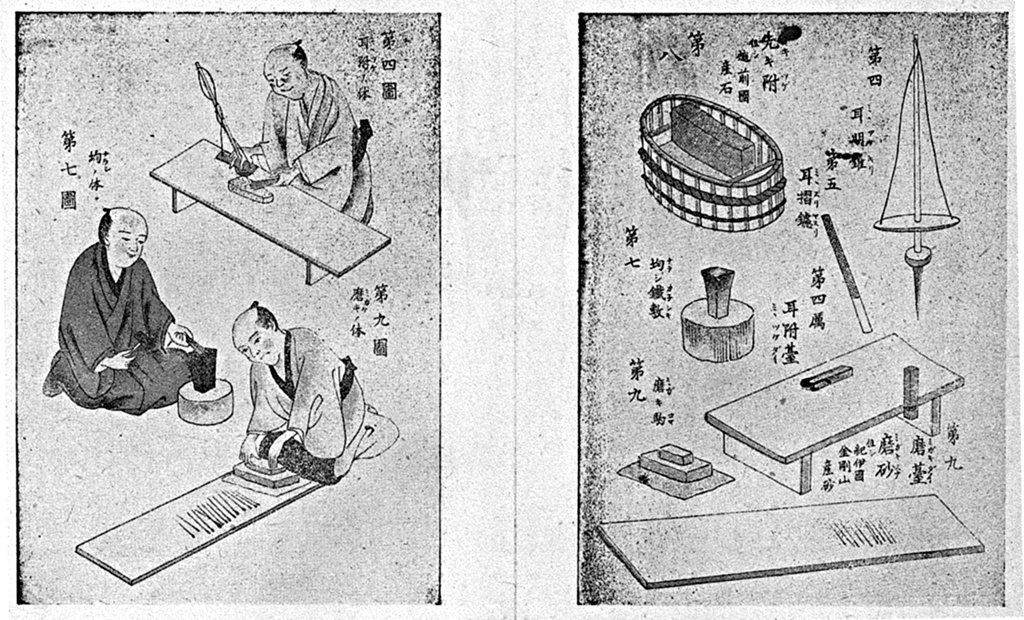

About 700 years ago, it is said that sewing needles were first brought from China to Nagasaki, and the manufacturing of needles in this country began there.

The origin of Himi needles is unclear, with various theories such as itinerant needle merchants who settled in Himi at the time of the arrival of Nagasaki needles,

or those who went to Nagasaki about four hundred and several decades ago and learned the manufacturing method.

However, at least, it was called "Nagasaki Seiden Needles," and the trademark also indicated that it was transmitted from Nagasaki,

with "Nagasaki Refining" written on it. About 280 years ago during the Genbun era (the era of Tokugawa Yoshimune),

in Chuo-cho, Himi Town, Tako [a certain person] engaged in the industry, and in the fifth year of Ansei,

Nidai Sakuemon 'Sakuemon 2nd' succeeded and instructed a separate production method, which flourished under Sandai Sakuemon 'Sakuemon 3rd'.

(2) Edo Period

In Himi, there was a group of craftsmen called "mirror polishers" (kagami togishi) who received the protection of the Kaga domain and went to work in other provinces during the agricultural off-season. Mirror polishers were artisans who polished and coated copper mirrors that had become cloudy or rusted, making them difficult to see. Their numbers gradually increased, but as glass mirrors (called "beidoro mirrors") replaced bronze mirrors, they gradually transformed into itinerant merchants selling small items such as tobacco cases, hair ornaments, mirrors, needles, and strainers. They expanded their clientele to the Chubu, Kanto, and Tohoku regions, and sewing needles in particular were highly regarded.

(3) Subsequent Events

Druggists in Toyama also used sewing needles as gifts distributed to various places.

(4) Record from around the 17th year of Meiji

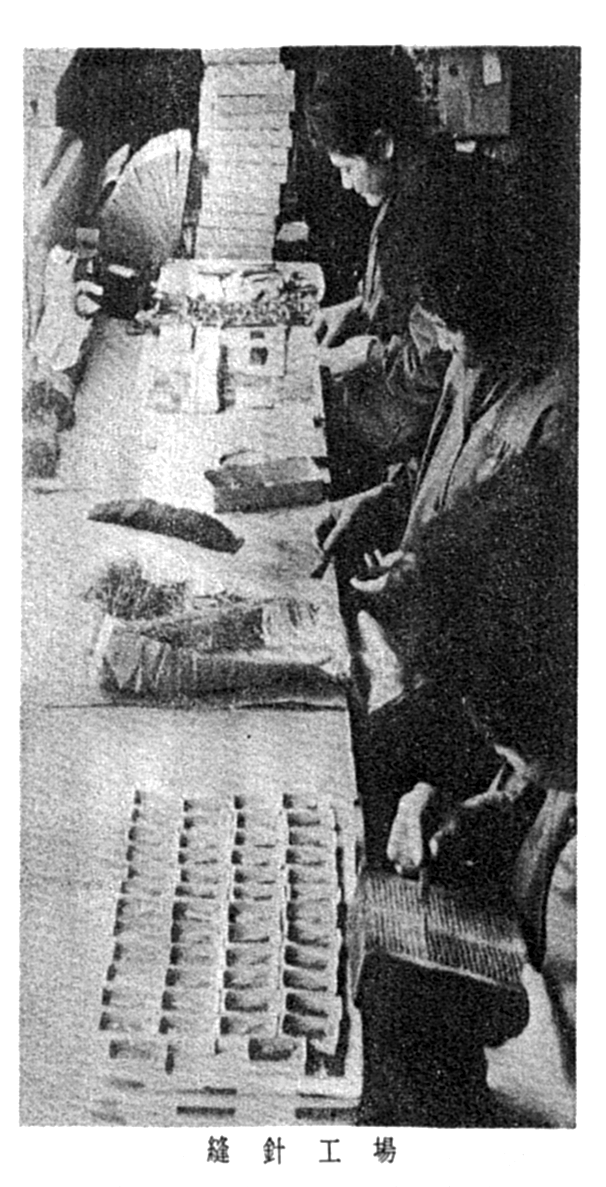

There were about 80 households engaged in sewing needle manufacturing (of which 70 were located in the former Shikiri-cho). In addition to the typical household production involving 2 to 3 people, more than 10 wholesalers owned their own factories, employing 10 to 50 workers for manufacturing. The raw needle material was purchased from Hamasaka (Hyogo Prefecture) and Hirakata (Osaka), and sales were primarily conducted by small merchants and sewing needle itinerant merchants, who traveled mainly to the Chubu, Kanto, and Tohoku regions during the agricultural off-season.

(5) Around the 37th year of Meiji

Machine production began, and with the use of power, production increased.

Amidst the sharp increase in export demand due to the Russo-Japanese War, in Meiji 41 (1908),

the "Kōshin Needle Company" was established as an industrial factory.

It used coke and smokeless coal as fuel and employed gas engines, producing with 40 to 50 workers (at its peak, 240 workers).

The chief engineer and manager of this factory was Kameya Kyuzaburo, who had long operated a needle wholesaler under the name "Aburaya".

Around Meiji 20 (1887), after seeing imported needles (German needles, British needles),

which were far superior in shape, luster, and quality to the traditional "Misuya Needles", it was recognized that Japan also needed to adopt machine-made needles.

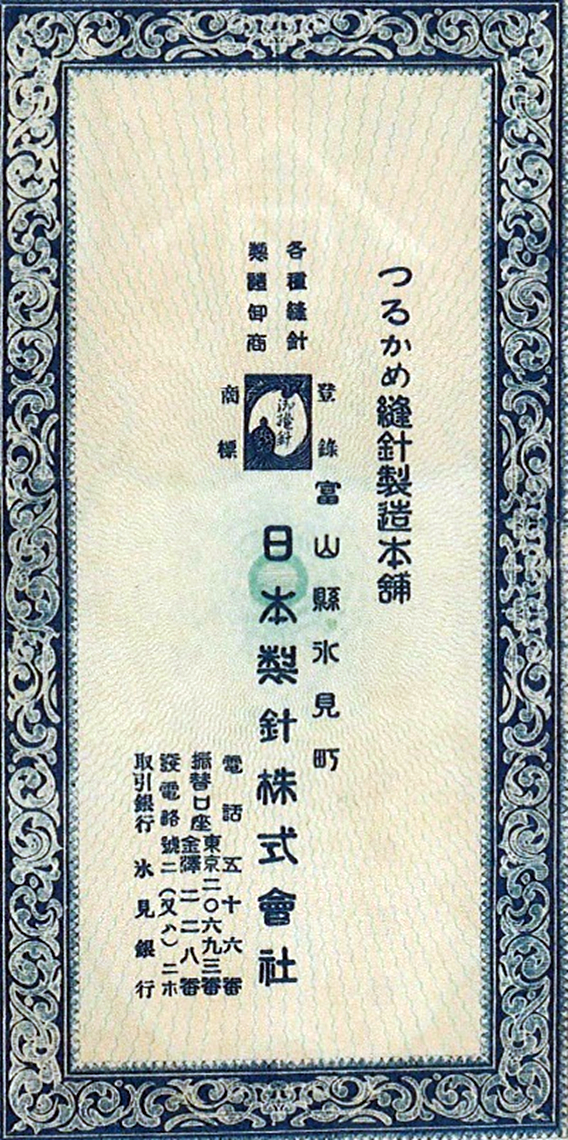

Therefore, from Himi, which was the center of needle manufacturing, to Kyoto, he founded the "Nihon Seishin Kabushiki Kaisha"

in Meiji 26 (1893), becoming the first person in Japan to purchase German-style machinery and start machine-made needle production with electric power.

However, there were difficulties in handling imported machinery at the time and the factory suffered damage from a fire caused by electrical leakage, leading to failure.

Invited to Himi, he became the central figure in technical guidance at this new factory and developed it to have a production capacity of 5 million needles per month.

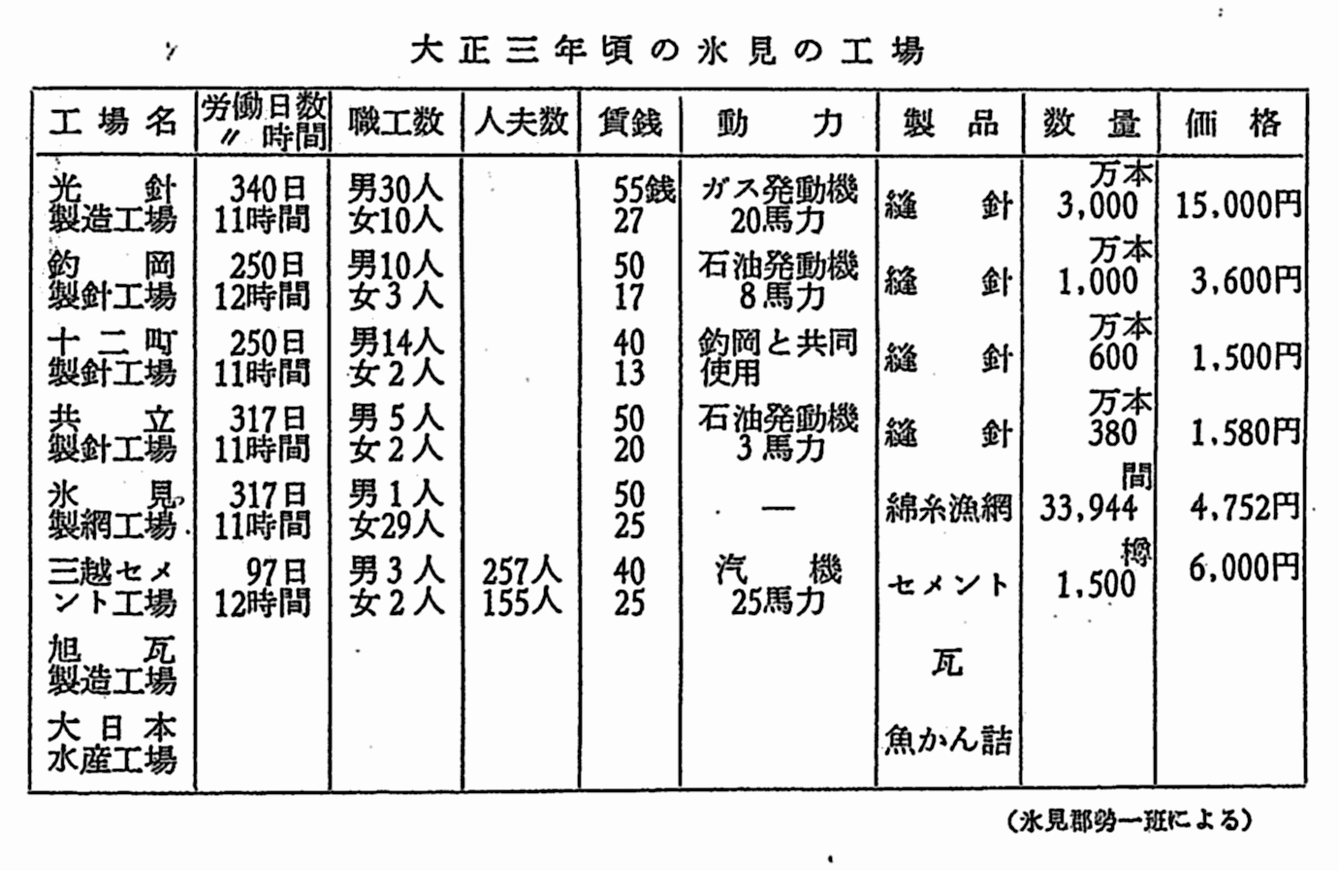

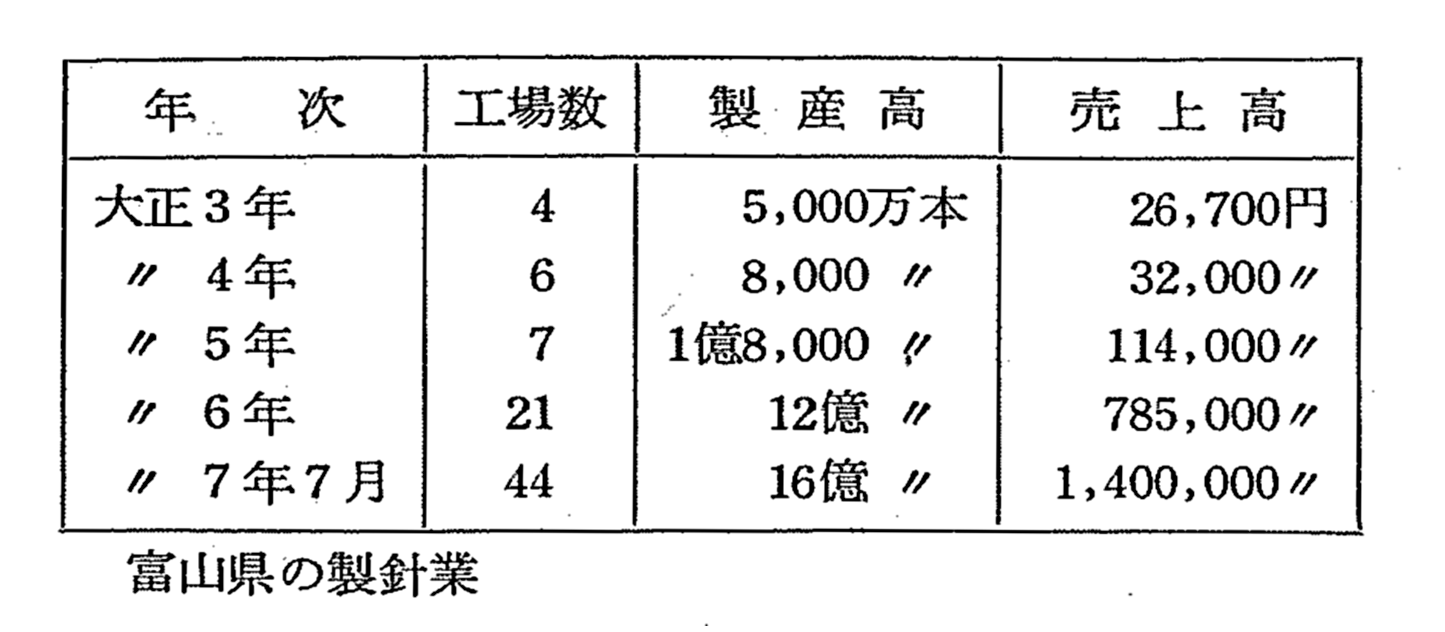

(6) Taisho Period

In July of Taisho 3 (1914), a war broke out in a corner of Europe.

At that time, the economic situation in Japan was severely depressed due to extreme economic recession, but European countries were unable to export due to wartime conditions,

particularly German needles stopped coming to the Asian market, leading to a booming sewing needle industry.

Orders flooded into Himi, and new factories were established one after another. Factories were also established in Isurugi, Takaoka, and Toyama within Toyama Prefecture,

expanding exports to Russia, China, Mexico, India, and other countries, making Himi the second largest needle production center in Japan after Hiroshima Prefecture.

According to records from Taisho 7 (1918), factories in Himi included Himi Seishin in Shikiri-machi,

Nihon Seishin, Toa Seishin in Ta-machi, Koshin Seizo in front of the station, Marubo Seishin in Goza-machi,

Nitto Seishin in Shin-machi, and Ame Seishin, Kyoukon Seishin in Shikiri-machi.

However, when Germany surrendered and World War I ended, poorly made sewing needles lost credibility, prices fell due to overproduction,

and bankruptcies and factory closures followed. By Taisho 15 (1926), the remaining factories were only Nihon Seishin

and two individuals, with an annual production of about 150 million needles.

(7) Transition to the Showa Era

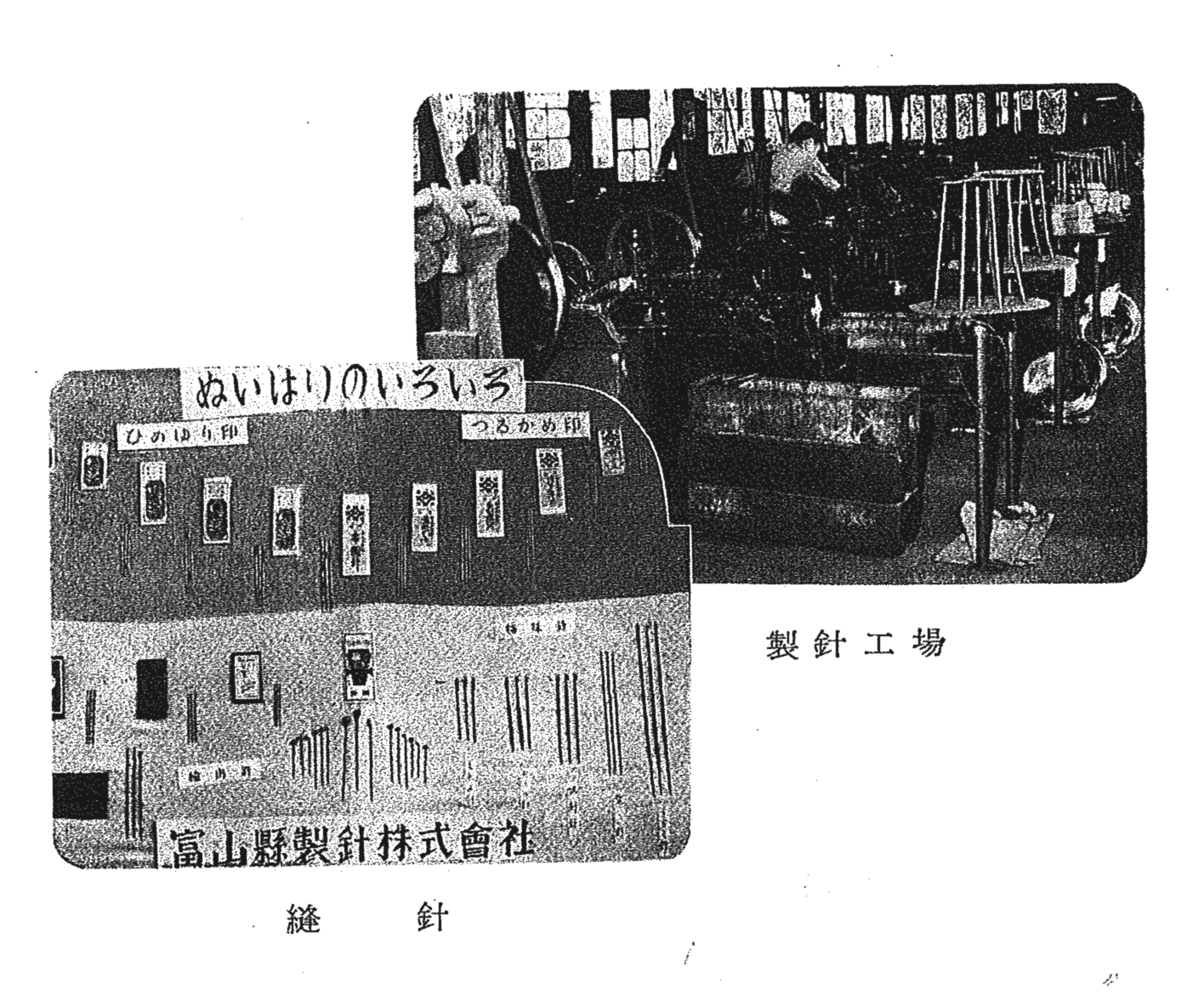

Afterwards, including companies that revived, Himi became one of the three major production areas in the country. They produced high-quality sewing needles such as Sale needles for the navy, but the production volume was small. In Showa 17 (1942), raw material control was implemented, and Nihon Seishin, Juni-chō Seishin, and Ame Seishin jointly established the Toyama Prefecture Needle Manufacturing Company.

Before the war, 15% of domestic demand was met by Himi, 80% by Hiroshima, and 5% by Hamasaka, Hyogo Prefecture. However, due to the destruction of the needle manufacturing industry in Hiroshima during the war, orders flooded into Himi, and for 2 to 3 years, the demand exceeded the supply. Showa 25 (1950) saw the beginning of the Korean War, which led to a sharp increase in demand mainly for India. It seemed to regain momentum, but production as a boom ended in a short period. Subsequently, as Hiroshima's production capacity recovered, sewing needle production began to concentrate in Hiroshima, and in addition, the demand for sewing needles itself decreased in line with changes in lifestyle. The last sewing needle manufacturing company in Himi, renamed Kenshin Industrial Co., Ltd., ceased its own production around Showa 50 (1975). After that, it shifted to manufacturing weaving machine parts using the sewing needle production technology, which continues to this day.

Reference Materials

| Nihon Hōhari Kō (History of Japanese Sewing Needles) |

Written by Shigeru Watanabe, published by Bunshodō | (Published in 1944) |

| Himi Machi Annai (Himi Town Guide) |

Himi Town Hall, Himi Chamber of Commerce and Industry | (Published in 1928) |

| Himi Shōkō Annai (Himi Industrial Guide) |

Himi Chamber of Commerce and Industry | (Published in 1940) |

| Himi no Fu (Records of Himi) |

Edited by Masakazu Shima | (Published in 1966) |

| Himi-shi Shōkō Nenkan (Himi Industrial Yearbook) |

Himi City Hall, Himi Chamber of Commerce and Industry | (Published in 1956) |

| Jitsugyō no Toyama 1995.11 Gatsu-gō (Practical Toyama 1995.11) |

This Person, This Job: Junkichi Ame | (Published in 1995) |

| Himi-gun Shi (Himi County Records) |

Himi District Office, Toyama Prefecture | (Published in 1909) |

| Himi Hyakunenshi (100 Years of Himi) |

Himi City Hall | (Published in 1972) |

| Himi no Rekishi, Minzoku (History & Ethnicity of Himi) |

Himi City Board of Education | (Published in 2003) |

| Himi no Shizen to Rekishi (Nature and Histroy of Himi) |

Himi City Board of Education | (Published in 1974) |

| Himi-shi-shi (History of Himi City) |

Himi City Hall | (Published in 1963) |

| Himi-shi-shi 2 (History of Himi City 2) |

Himi City Hall | (Published in 2006) |

| Himi no Senken Dai 1-shū (Pioneers of Himi Vol.1) |

Himi City Board of Education | (Published in 1976) |

| Hyōdai Fumei Kōmoku Himi Hari (Untitled Article on Himi Needles) |

Takaoka Commercial High School | (Published in 1940) |